Brick Wall Calculator

Mixing Precautions for Masonry Mortar

Material Preparation

- Cement: Select the appropriate cement type and strength grade according to engineering requirements.

- Sand: Use clean, impurity-free sand, generally medium-sized sand.

- Water: Use clean water.

Proportion Determination

- Cement-Sand Ratio: Typically, the cement-sand ratio ranges from 1:2 to 1:6 (cement: sand), depending on the mortar's strength grade and intended use.

- Additives: If needed to enhance certain properties of the mortar (e.g., bond strength, impermeability), additives such as lime putty, fly ash, plasticizers, etc., can be added in proportion. However, note the type and quantity of additives to avoid affecting mortar quality.

Mixing Process

- Dry Mixing: First, mix cement and sand in the determined proportion using tools like a shovel until the color is uniform.

- Wet Mixing: Gradually add water while stirring until the mortar reaches the desired consistency and uniformity. Stirring should last for no less than 2 minutes to ensure mortar uniformity and fluidity. If additives are used, stirring time should be extended to at least 3 minutes.

- Mechanical Mixing: Whenever possible, use mechanical mixing, such as with a mortar mixer, to more effectively ensure mortar uniformity and quality.

Precautions

- Material Quality: Ensure cement and sand quality meets requirements, free from impurities and pollution.

- Accurate Proportion: Strictly follow the determined proportion during mixing to avoid mortar performance degradation due to proportion imbalance.

- Uniform Stirring: Stir evenly to ensure cement and sand are fully mixed, avoiding dry powder or clumps in certain areas.

- Use Immediately: Mix mortar as needed and avoid long-term storage, which can lead to performance degradation. Especially in high temperatures, shorten storage time to prevent mortar from hardening.

- Safety Measures: Wear appropriate protective equipment, such as masks and gloves, during mixing to prevent dust from harming the body.

Formulas Used:

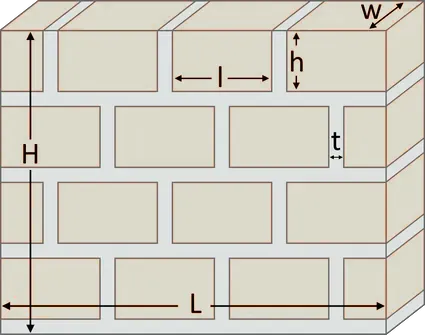

Step 1: Wall Volume

Formula: Length × Width × Wall Thickness

Step 2: Brick Volume

Formula: Brick Length × Brick Width × Brick Height

Step 3: Brick with Mortar Volume

Formula: (Brick Length + 0.01) × (Brick Width + 0.01) × (Brick Height + 0.01)

The thickness of the mortar is 1.0cm

Step 4: Number of Bricks

Formula: Wall Volume / Brick with Mortar Volume

Step 5: Total Brick Volume

Formula: Number of Bricks × Brick Volume

Step 6: Mortar Volume

Formula: Wall Volume - Total Brick Volume

Step 7: Total Mortar Volume with Waste

Formula: Mortar Volume × 1.15

Step 8: Dry Mortar Volume

Formula: Total Mortar Volume with Waste × 1.25

Step 9: Cement Volume

Formula: (Cement Ratio / (Cement Ratio + Sand Ratio)) × Dry Mortar Volume

Step 10: Number of Cement Bags

Formula: Cement Volume / 0.035

Step 11: Sand Volume

Formula: (Sand Ratio / (Cement Ratio + Sand Ratio)) × Dry Mortar Volume

Step 12: Sand Weight

Formula: Sand Volume × 1550 kg

Step 13: Calculat Cost

Formula: Total Cost = Brick Cost + Sand Cost + Cement Cost + Worker Cost

Home

Home Back

Back